My story at LEONI

I am Tony and have been employed at LEONI in Roth since September 2017. I started as a career changer from a different field of work to become a “coiler”. This work is performed in a 3-shift system comprising alternating early, day, and night shifts. Over time, I also learned the whole span of work in this section. In October 2022, I transferred to the Jacketing department to educate myself further, and there I now look after my own machine.

This is my job

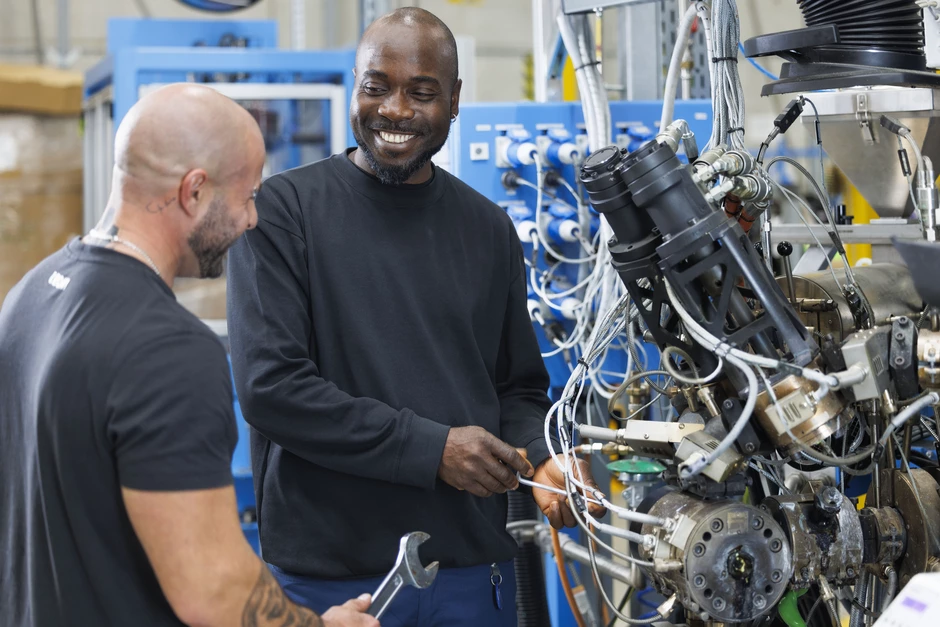

As a machine operator, my task, hand in hand with my colleagues, is to work on my line as well as with product development, and to coordinate work processes with them. Furthermore, it is important to precisely adjust my machine to achieve the desired result with the end product. My area of responsibility also includes preparing the material (operating the dryer), setting the right cable color and markings as well as running the extrusion as specified.

What I love about my job is accepting a new challenge with every new order. Each of these is multifaceted and requires careful processing. It is also great when you start on an order, give it your best (according to the specifications) and everything goes perfectly from the outset, just as it should be. Yet sometimes we’ll find that some optimization is still needed. This might involve either adjusting the work process (re-adjusting the machine) or suggestions for improving the product. This happens in close collaboration with my supervisor and product development. In short, it thrills me to always be working with full commitment.

My daily routine

Start of the day

The start to my day differs a lot depending on the shift, and begins by driving to LEONI and with the shift handover,

which involves being informed of anomalies, malfunctions, the progress of production as well as possibly pending additional orders. Thereafter I go to the line to execute the pending orders.

Lunch break

There is no set lunch break in our department because the machines cannot just be switched off. Depending on the order situation, we use any opportunity here and there to eat something or get a few bites from the snack vending machine.

Afternoon

As I continue to be at my line, I continue to operate it as usual. Before my shift ends, I hand the line including all information on the orders and events during my shift over to my colleague doing the next shift.

Evening

Depending on the shift, I finish at either 2 p.m., 10 p.m. or 6 a.m. And depending on that, I will either head directly to bed (usually in the case of night or day shift), spend time with my family, or go the gym to stay healthy. We also like to do that as a family. I furthermore commit leisure time to voluntary work for the Technisches Hilfswerk charity.

My highlight

My most exciting moment was when I had a tour of the factory floor during my interview. I found it totally fascinating to see how many different pieces of equipment and work processes there are to create a cable. That was completely new to me as I had done a different job before that did not have anything to do with machine production.

My view of LEONI as an employer

What I appreciate very much at LEONI is that my colleagues and managers accept me without any problems or prejudices despite my migrant background. This company is also very family-friendly, which means that you can combine your job and family time very well.

The atmosphere in my team, furthermore, is very pleasant. Now and then, we like to laugh and joke around together. When there are problems or questions arise, we try to support and help each other as best we can. We can thus clear up smaller-scale problems within the team ourselves as well.

In three words, I would describe LEONI as international, forward-looking, and modern.

![[Translate to English:] [Translate to English:]](https://d3ga0yfowtcnef.cloudfront.net/fileadmin/_processed_/2/c/csm_Bild1_cf6b1059b9.webp)