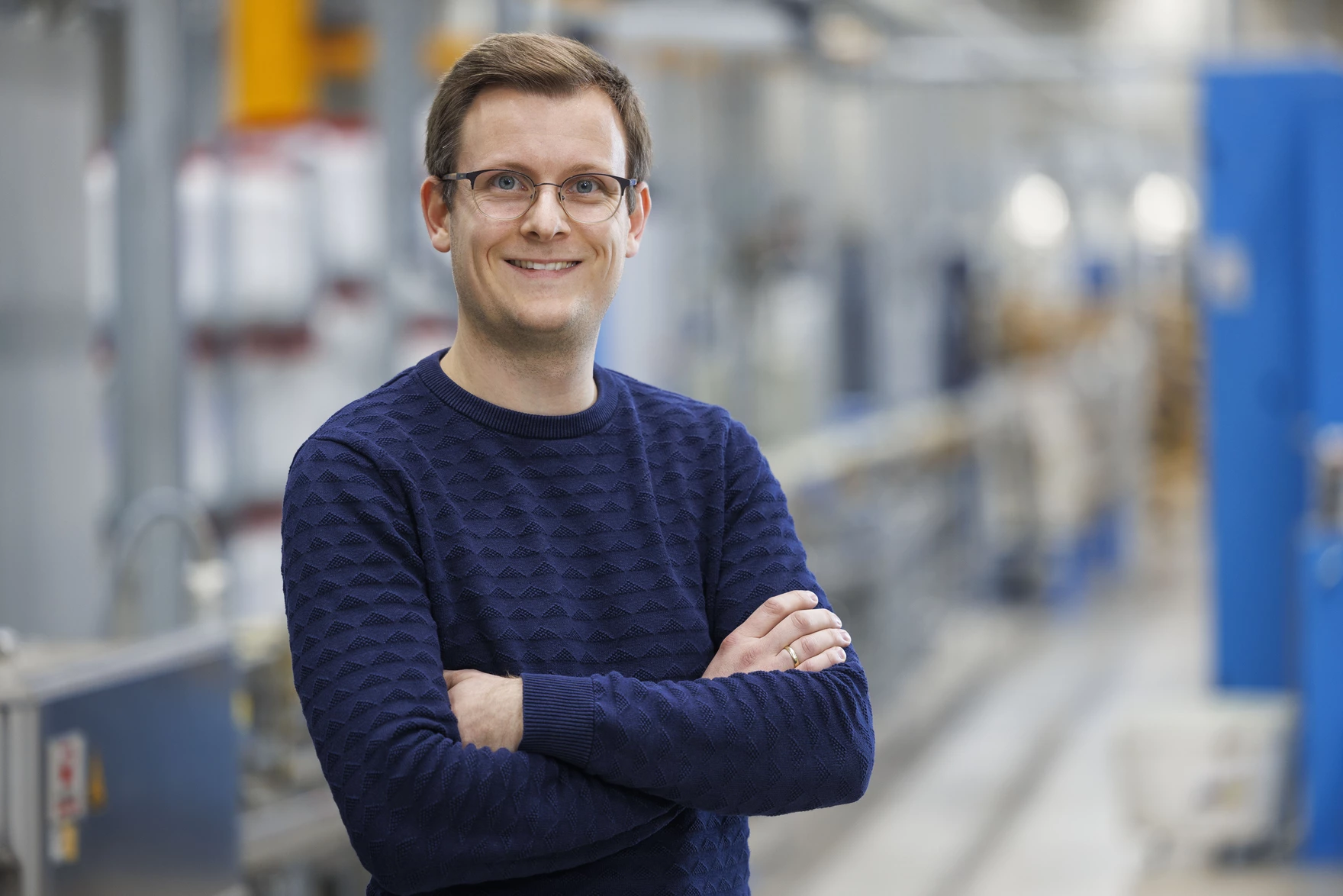

My story at LEONI

I’m Andreas, 33 years old and began my career at LEONI in 2007 in Roth. Originally, I completed an apprenticeship to qualify as an industrial mechanic and broadened my qualifications in 2013 through a LEONI scholarship that enabled me to graduate as a certified plastics process engineer. After graduating, I returned in August 2015 by joining the Technical Training team and, as Junior Coordinator, took on the task of qualifying, inducting, and training colleagues and apprentices. Since January 2021, I have been working as a production engineer in the Industrial Engineering department.

This is my job

In my role as a production engineer, I am responsible for generating targeted documentation, leading workshops, supporting implementation, and servicing new plant and components as well as training staff. Alongside my industrial engineering work, I am responsible for the practical training of our apprentices to qualify as machine and equipment operators. In addition, I am involved on the Audit Committee of the Chamber of Industry and Commerce and function as reviewer of the audits.

In this context, I take the opportunity to gather the feedback from our machine operators and thus to keep up to speed regarding possible malfunctions or problems in production.

My daily routine

Start of the day

My working day usually starts at 6.30 a.m. in the office where my morning routine begins with unpacking and booting up my computer. Thereafter I take a short tour through production, in particular going through our material supply line to check it for possible faults.

Morning

After that tour and depending on the tasks at hand, I first take a look at my email inbox and the upcoming meetings in my calendar. I subsequently take care of various tasks on my computer or support our production departments in a variety of operations.

Lunch break

The timing of my lunch break varies depending on my appointment calendar. If possible, I head to our canteen at about 12 noon to join my colleagues for lunch, to share information and thoughts with them as well as to socialize.

Afternoon

After my lunch break, I frequently devote my meeting-free time to visiting apprentices working in production.

I mostly spend the remainder of the afternoon on my computer to work on emails and projects. Alongside the aforementioned tasks, this also involves administering and maintaining our tools management for production tools as well as our printing systems for marking our products.

My highlights

LEONI has given me numerous unforgettable moments, beginning with my first day at LEONI and the start of my apprenticeship, which takes top spot for me. This also includes independently planned and run staff training sessions for other locations.

However, my two stints in China in 2016 and 2017 were the absolute peak of my time at LEONI. Together with my boss at the time and the chief instructor of Technical Training, I supported the training of machine operators in the teaching workshop that he had set up in Changzhou. Our task was to optimize training in China, to share information with our colleagues and furthermore to run promotion at the technical colleges.

My view of LEONI as an employer

The outstanding work culture and team atmosphere at LEONI is reflected in respectful interaction. We treat each other as equals here and always enjoy recognition. Any conflicts are resolved objectively and without personal sensitivities, within both the team of instructors and our department. The familiar atmosphere in the team, where we are all on first-name basis, enables open communication about professional and personal challenges. This family-like relationship is evident especially clearly during such joint activities as seminars and our Christmas party where easy conversation and suggestion sharing is cultivated.

Overall, LEONI can be briefly and succinctly described as multifaceted, stable, and respectful.

My tips for future colleagues

I encourage every new colleague to be open and ready to confront new challenges without hesitation. If you have questions, it’s worth approaching “old hands” and peppering them with concerns. It has not yet happened during my time at LEONI that I was refused help. Anyone who asks will always be helped.

Regardless of whether it's a professional or personal matter, I'm always ready to answer questions or, if necessary, provide contacts and offer my help to colleagues.

![[Translate to English:] [Translate to English:]](https://d3ga0yfowtcnef.cloudfront.net/fileadmin/_processed_/2/c/csm_Bild1_cf6b1059b9.webp)